LIQUID COATING

- Two clean / enclosed paint systems

- Three-Stage manual spray gun production line

- Multi color production runs (Mate, Semi, & High Gloss)

- 3k-5k pieces / shift production capacity

- A 20 W in x 40 in H x 20 in L (size piece)

- 600 linear feet conveyor

- Up to 10 feet per minute velocity

- 100 to 450° F conventional oven

- 10 to 55 minute curing time

Engineering – Technical Expertise

Technical staff with expertise in finishing process including, tooling, development and materials.

Comprehensive project management from concept through production, integrated with APQP processes.

Design support services, as well as manufacturability assist.

Experience with a vast range of paint options (Liquid / Powder).

CAD capabilities (Solid Works, & AutoCAD.

Design, Construction, refurbish and installation of complete paints systems including pretreatment drying off / curing ovens, paint booths (manual – automated), tooling, racks, hanging fixtures and conveyors.

What we know how to do

Our Clients

We work together with our clients with the Jobs to be done concept.

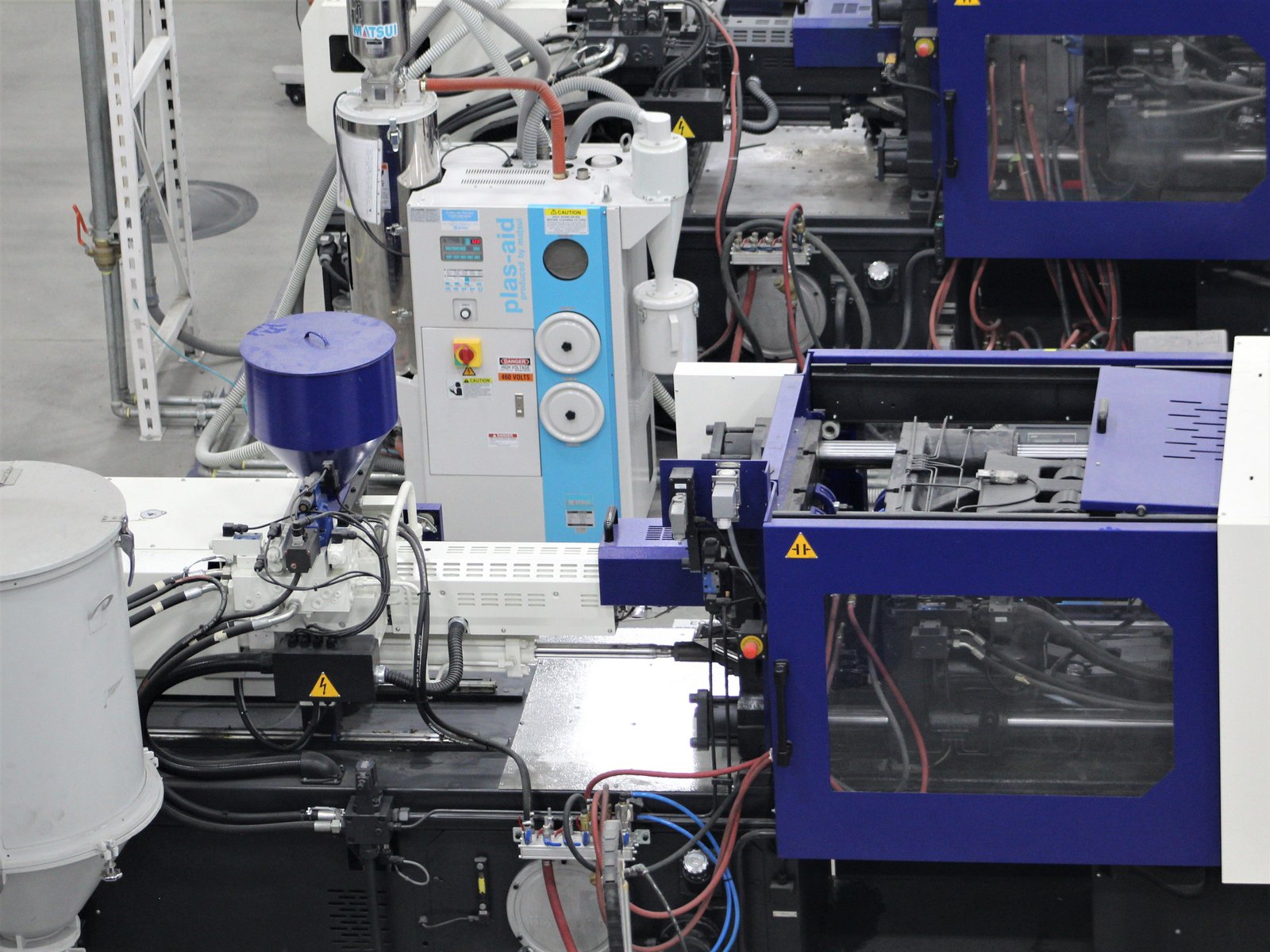

Plastic

Plastic  Powder

Powder