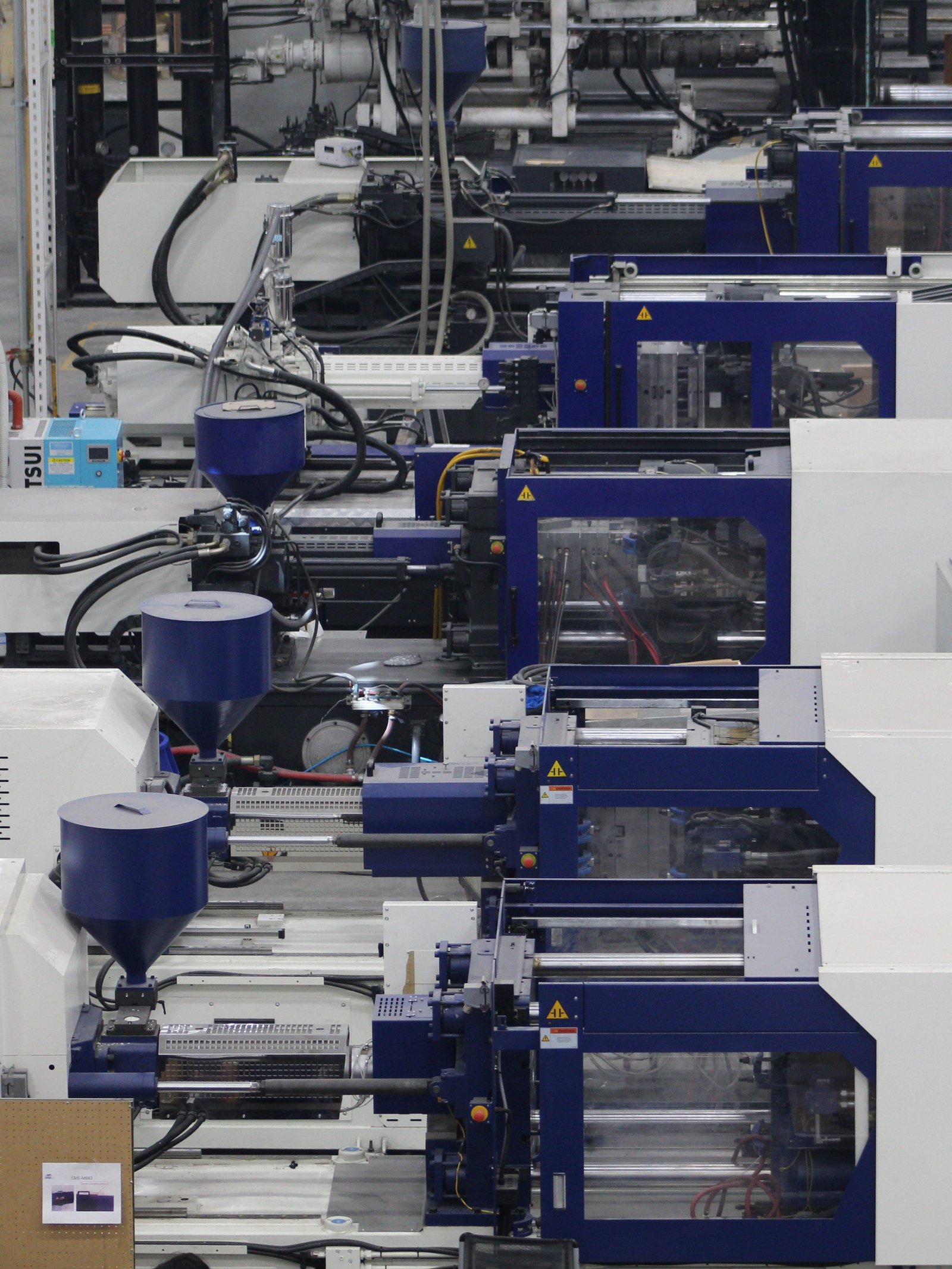

PLASTIC INJECTION

- 60, 90, 120, 160, 190, 250, 320 and 1250 Ton press

- Crane 20 Ton capacity overhead

- Molding area of 75, 000 square feet

- Warehouse for 1,000 decks of 40 x 48 inch

- Mold design / prototype / validation

- Secondary operations

- Assembly & packaging

- Molding Manager Engineer with 26 years’ experience in plastic process and management.

- Maintenance Manage Engineer with 22 year experience.

- All Molding and Maintenance technicians + 10 year experience in plastic technology.

- Mold Maintenance, and Repair

- Product & Mold Design / Development / Consulting

- High Precision Tooling and Molding (EDM machining)

- Medical / Automotive / Appliances Tooling manufacture

- Mold Flow Analysis

- Multi-level Engineering changes

- Design for Manufacturing (DFM)

- Laser Welding / Engraving Management

- Fixtures / Gauges

- IGs

Engineering – Technical Expertise

Technical staff with expertise in finishing process including, tooling, development and materials.

Comprehensive project management from concept through production, integrated with APQP processes.

Design support services, as well as manufacturability assist.

Experience with a vast range of paint options (Liquid / Powder).

CAD capabilities (Solid Works, & AutoCAD.

Design, Construction, refurbish and installation of complete paints systems including pretreatment drying off / curing ovens, paint booths (manual – automated), tooling, racks, hanging fixtures and conveyors.

What we know how to do

- Cold & Hot runner / Multicavity

- Prototype mold / 2K & 3K mold

- Quick change mold

- High Temperature Mold

Liquid

Liquid  Powder

Powder